This tool features a patented chuck that is both easy to use and structurally stable, providing excellent sealing performance and high efficiency. It is capable of clamping square, round, elliptical, and I-beam pipes, among others. There are three chuck processing modes available to handle cutting head tailings between various chucks. The zero tailings mode helps to lower material costs. This tool is capable of quickly loading, cutting, and unloading pipes with high efficiency and quality, depending on their lengths, shapes, and specifications. It is widely used in various industries, including fitness equipment manufacturing, automobile production, thermal insulation container production for office furniture storage, agricultural machinery operation at high altitudes, and hardware product production, among others.

Laser tube pipe cutting machines have revolutionized the way metal tubes and pipes are cut in the manufacturing industry. These machines use a high-powered laser beam to cut through metal with precision and accuracy, resulting in clean and smooth cuts.

One of the main advantages of laser tube pipe cutting machines is their speed. They can cut through metal at a much faster rate than traditional cutting methods, reducing production time and increasing efficiency. Additionally, laser cutting is a non-contact process, which means that there is no physical contact between the cutting tool and the metal, reducing the risk of damage or deformation.

Laser tube pipe cutting machines are also highly versatile. They can cut through a variety of metals, including stainless steel, aluminum, and copper. This makes them ideal for use in a wide range of industries, including automotive, aerospace, and construction.

In terms of precision, laser tube pipe cutting machines are unmatched. They are capable of cutting through metal with a high degree of accuracy, up to 0.1mm. This level of precision ensures that the finished product is of the highest quality, with minimal waste and minimal need for further processing.

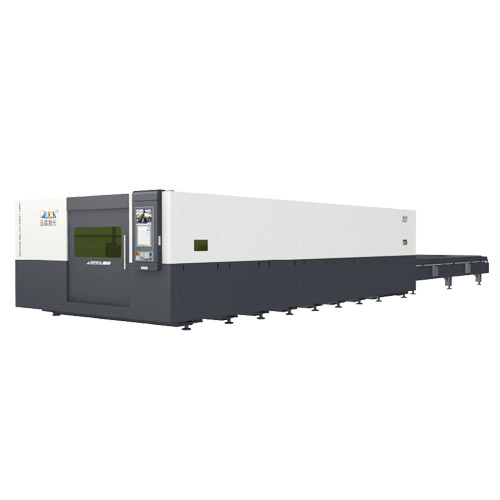

The Quick-PC machine is an advanced fiber laser cutting machine with a full protective cover design. It boasts a wide range of machine power, with options ranging from 1000W to 30000W.

With our 3D and 2D laser cutting machines, we can handle any application, regardless of lot size, sheet size, or thickness.

Our design and engineering teams have worked with customers from every industry to design, manufacture, and deliver marking solutions built for specific applications.

Metals to polymers, thick to thin, large to small, lasers can do it all. we can offer you comprehensive advice for all production possibilities.

Customer Service Products Privacy Imprint Company

2023 Air Tronics