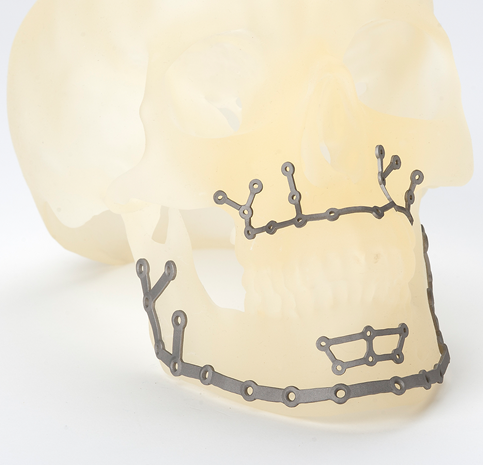

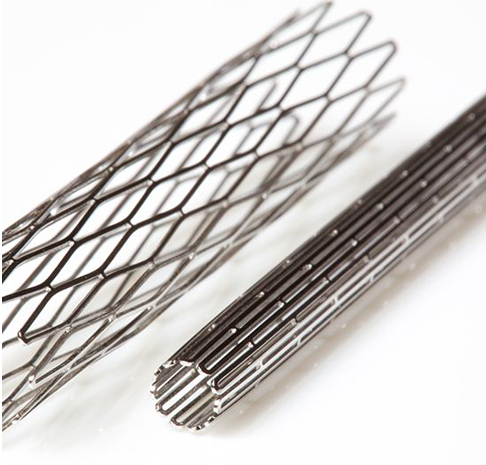

At Air-tronics, we specialize in providing microfluidic sensing devices that have exceptional dimensional accuracy and hole quality, thanks to our state-of-the-art laser drilling technology. Our laser equipment, which includes Flat Bed Cutting and Multi-Axis systems, can be programmed to meet the precise fabrication needs of this industry, demonstrating our expertise in cutting and welding. Additionally, our laser welding and cutting technology meets high-quality standards for clean surfaces with no material residue. You can trust us to provide you with the highest quality parts that meet your specific requirements.

APPLICATION ENGINEERING

Successful laser solutions

Using Air-tronics's fiber lasers for laser marking offers device manufacturers an efficient and corrosive-resistant process to uniquely identify stainless steel surgical instruments and composite-polymer catheters without the use of adhesives and primers. Laser welding using Air-tronics Fiber Lasers produces polymer bonds with consistent tensile strength, eliminating the need for adhesives and primers. Every device has different processes, but Air-tronics provides light sources and laser systems adaptable across many product lines and processes. Our light sources and laser systems are able to meet cost constraints while providing diversity in manufacturing for the medical device industry.

+86 18151106863

+86 18151106863 info@airtronicstech.com

info@airtronicstech.com