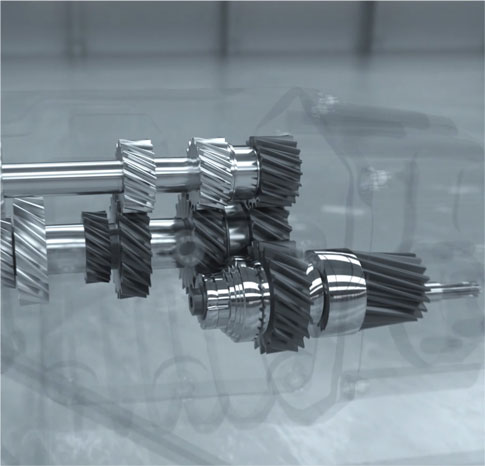

Our innovative laser solutions can effectively process traditionally difficult materials such as copper, galvanized steel, high strength steel, aluminum, and plastics. We confidently face the challenges associated with manufacturing and lightweighting e-mobility. Join us and experience the benefits of our novel laser solutions.

With laser processing, we can significantly improve the effectiveness, efficiency, and cost-effectiveness of intelligent manufacturing in the automotive industry. We have successfully provided solutions for more than 100 customized projects each year.

APPLICATION ENGINEERING

Successful laser solutions

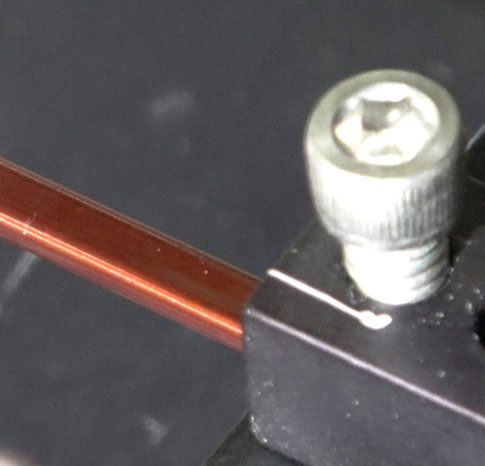

At AeeFar Airtronics Tech, we pride ourselves on providing the automotive industry with innovative fiber lasers that are essential for cutting, welding, marking, engraving, and brazing processes. Our fiber lasers are also an enabler technology in value-added remote welding, seam welding, and tube and profile welding applications. As the trend towards lightweight vehicle designs gains momentum, fiber lasers have become an indispensable part of today's highly automated and flexible production lines. With our fiber lasers, automakers can benefit from reduced operational costs, which can even be shared among multiple process stations with our novel beam switch technology. Our fiber lasers are easy to integrate, flexible, and user-friendly, requiring minimal maintenance or consumable parts. Choose AeeFar Airtronics Tech for compact yet highly efficient fiber lasers that deliver low operating costs and maximum output for your automotive needs.

+86 18151106863

+86 18151106863 info@airtronicstech.com

info@airtronicstech.com