Laser Marking

What is Laser Marking?

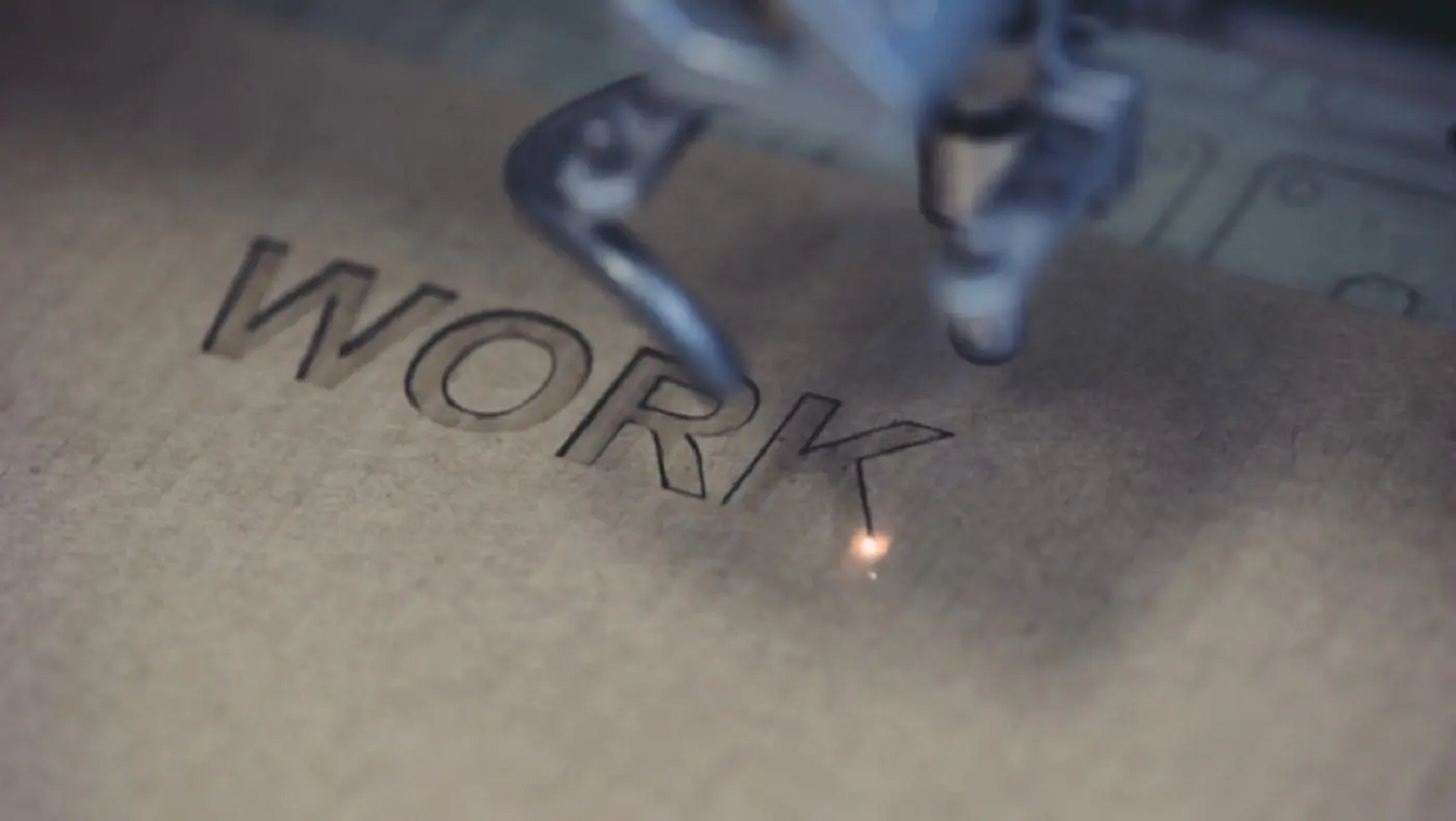

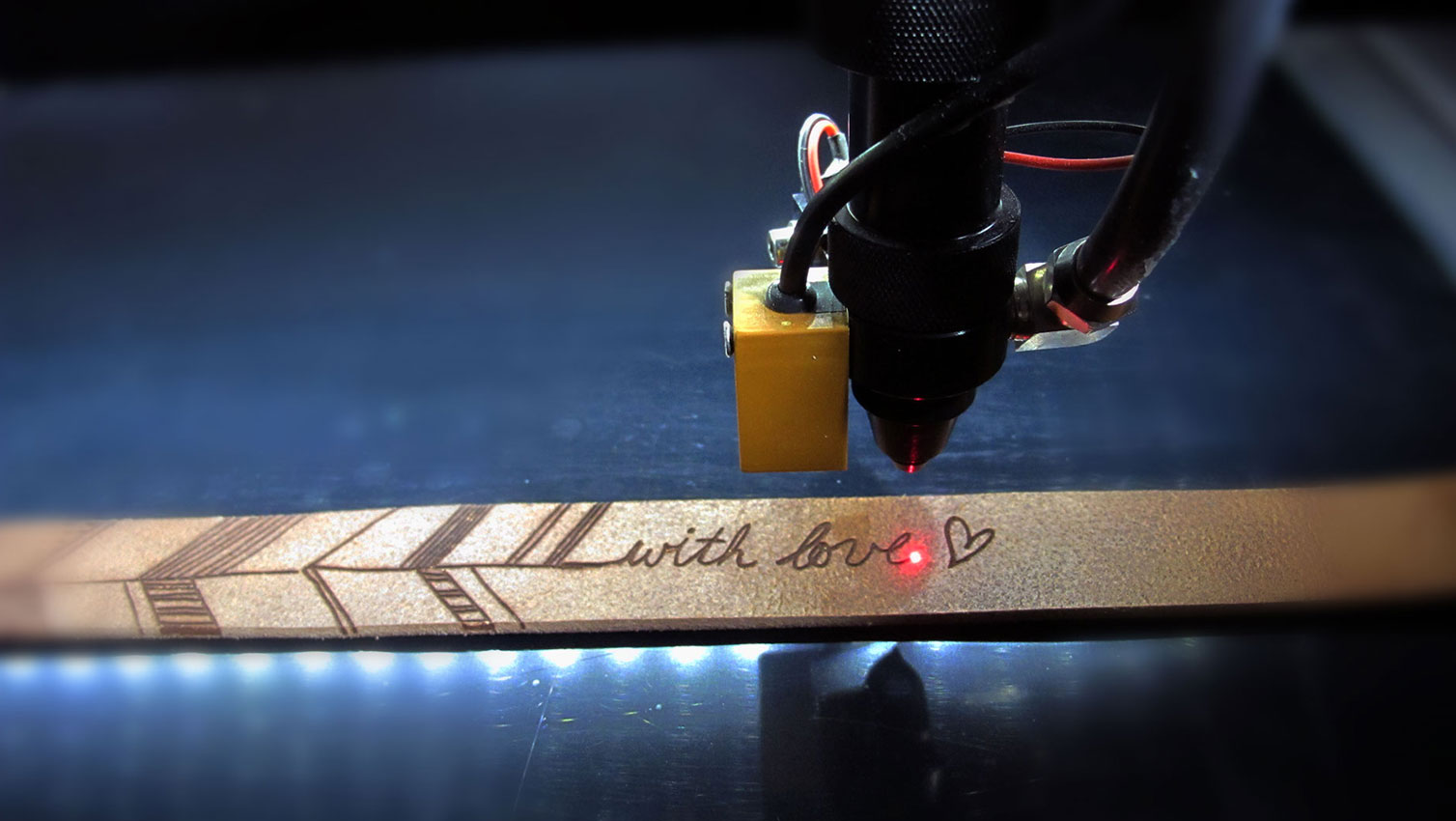

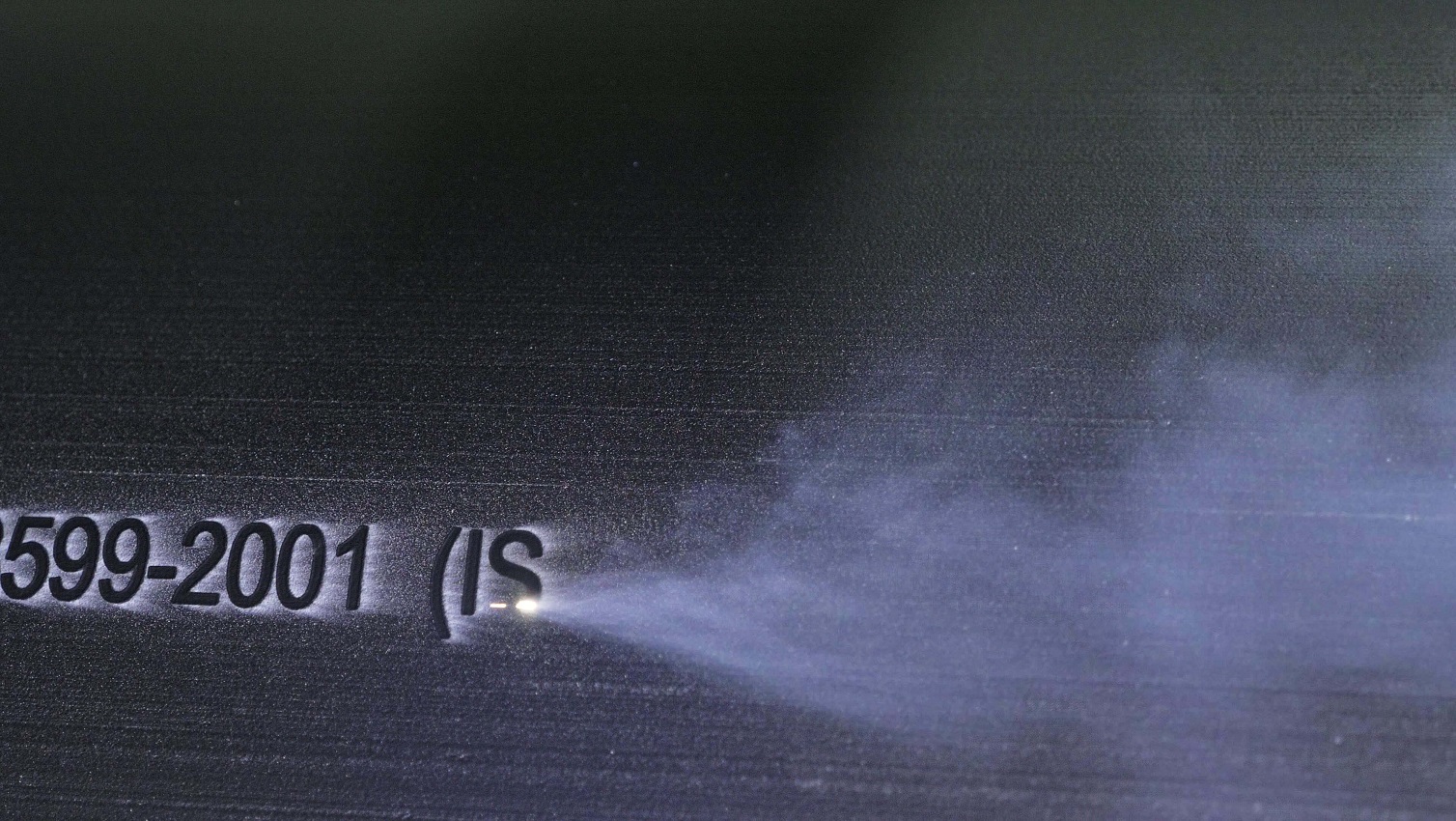

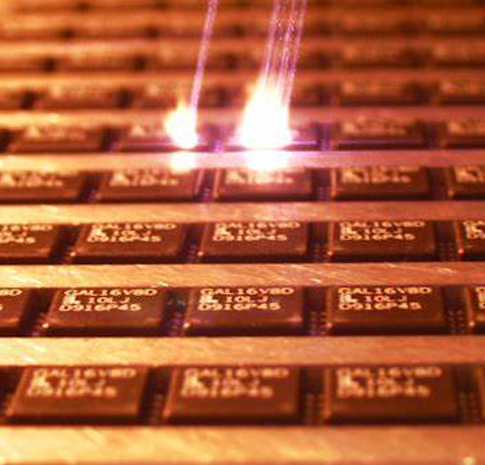

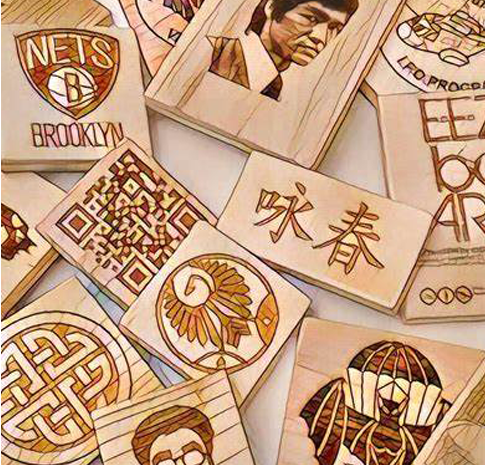

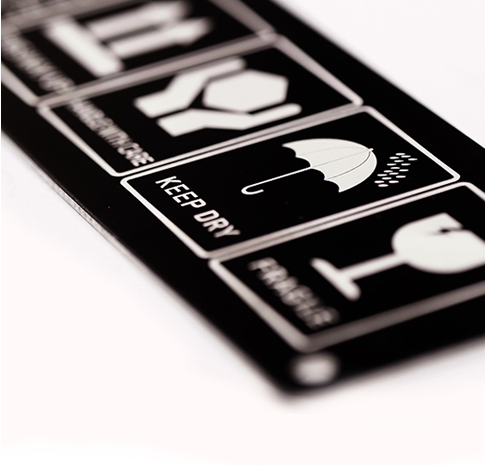

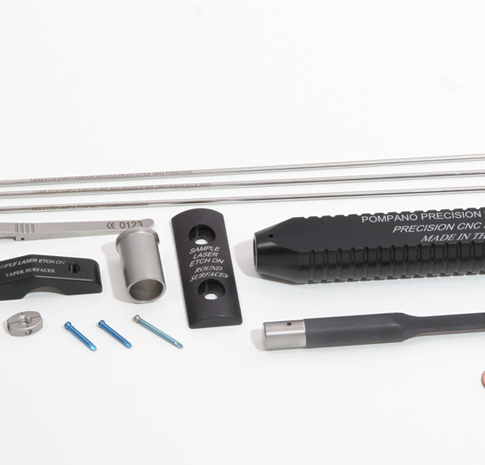

Laser marking is the cutting-edge technology that enables you to create permanent, non-contact marks on an object without any direct touch. With the help of a powerful laser, you can create intense heat in a small area, causing the material to melt or evaporate in that spot. This leaves behind enduring marks of any size with exceptional speed and accuracy. Whether you're marking text, codes, or symbols, laser marking ensures high-quality results with excellent contrast, without any compromise in speed or reliability.

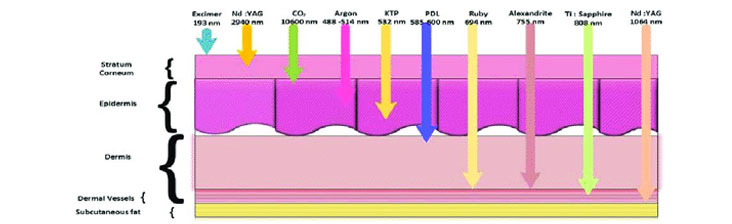

Laser marking is a highly effective method that utilizes an intensive pulsed laser beam to directly mark surfaces. Through the interaction of this focused beam with the surface, material changes occur, resulting in discoloration, structuring, engraving, or removal, depending on the wavelength, pulse duration, and irradiance of the laser beam. This process is an excellent choice for achieving precise and permanent markings on a wide variety of materials.

+86 18151106863

+86 18151106863 info@airtronicstech.com

info@airtronicstech.com