Laser Cutting

What is Laser Cutting?

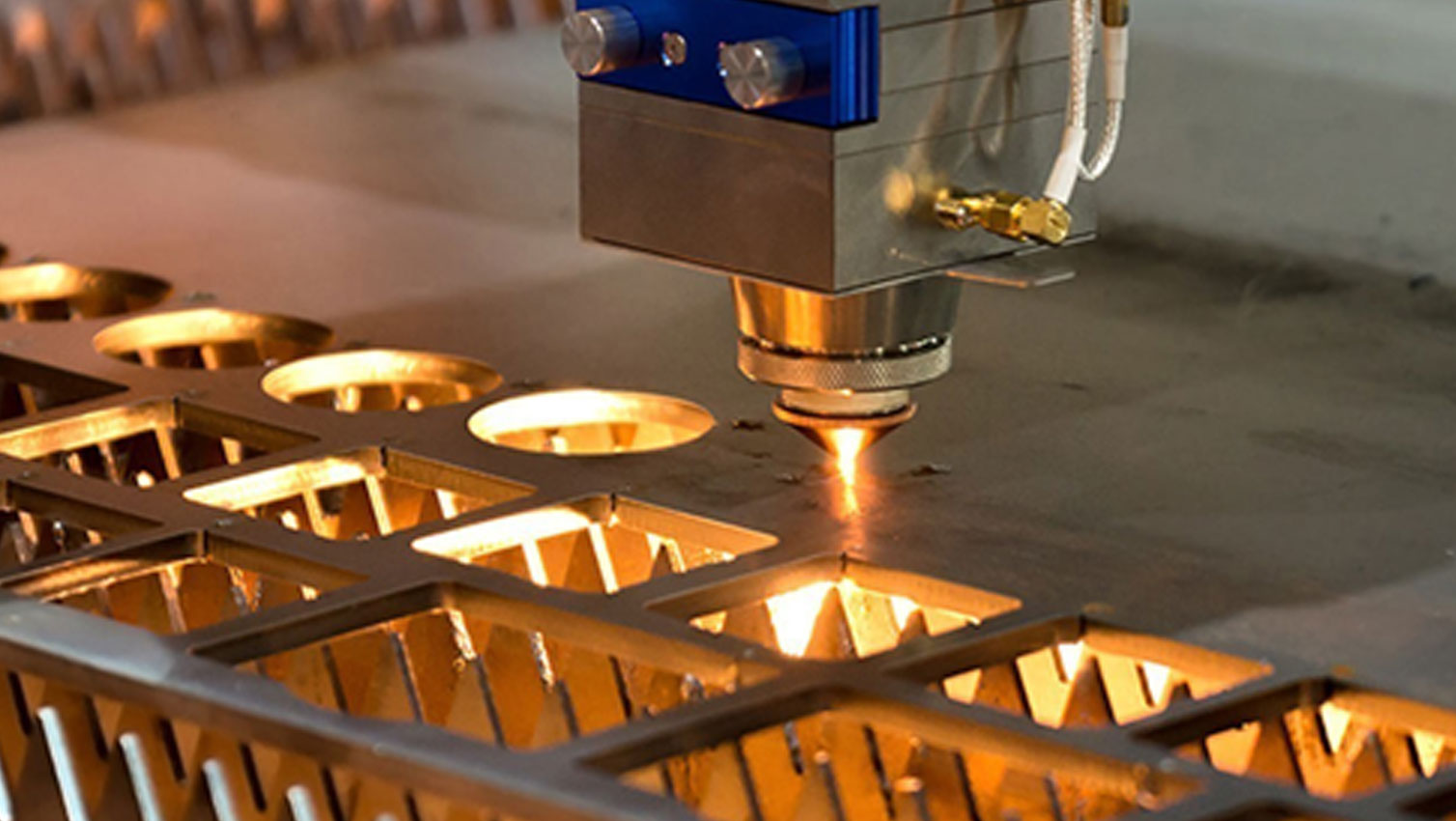

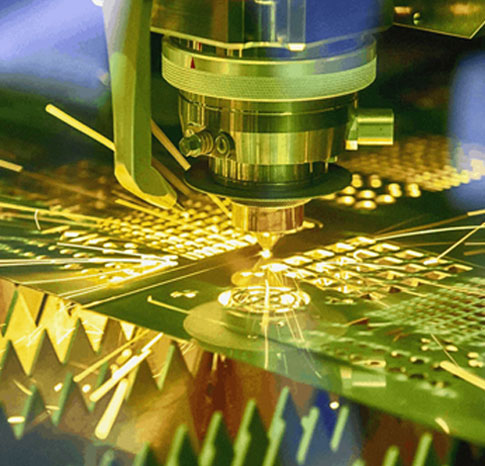

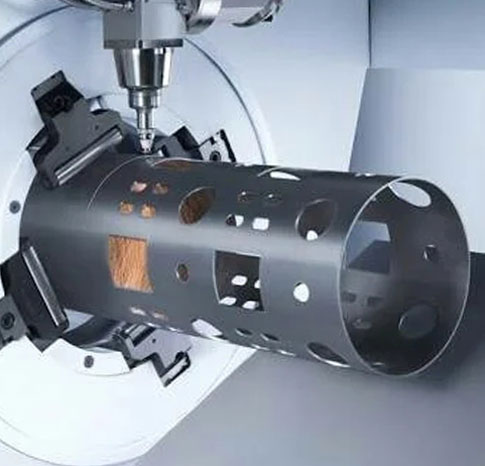

Laser cutting is a highly efficient method that employs intense heat, or "Thermal Cutting," to slice through a variety of materials. It has become a popular alternative to traditional methods due to its advantages, such as increased precision, durability, low power consumption, and faster tool changes. This technology is widely used in industrial manufacturing, with Fiber and CO2 Laser machines being the most popular, contributing to the development of the manufacturing industry.

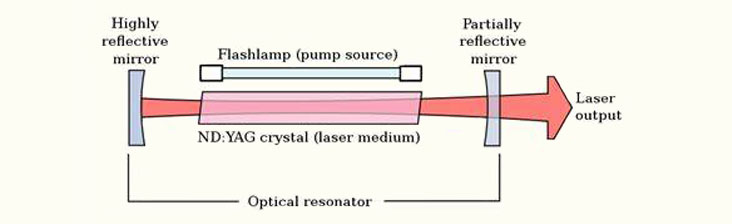

Laser beams are emitted from their sources and travel through optical equipment such as collimators and focusing systems before reaching material surfaces. The material is then heated to the point of melting or vaporization by the focused beams. After that, gas is used to remove melted or vaporized material from the beam's path, which results in cutting with movement of the laser beam.

+86 18151106863

+86 18151106863 info@airtronicstech.com

info@airtronicstech.com