Laser Cleaning

What is Laser Cleaning?

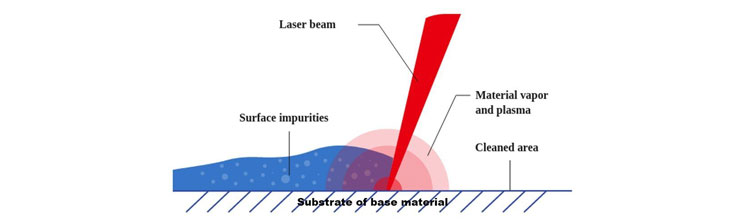

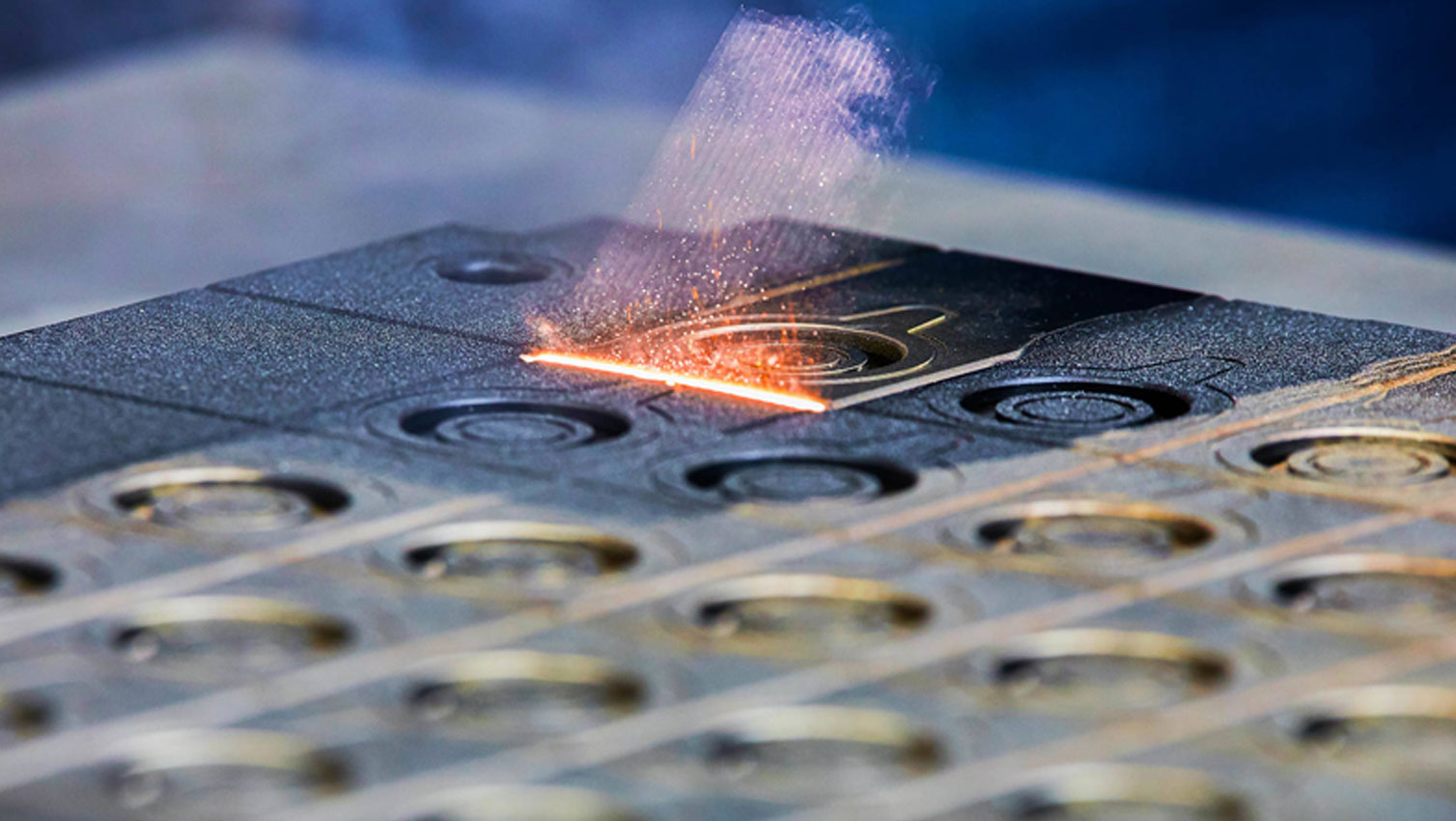

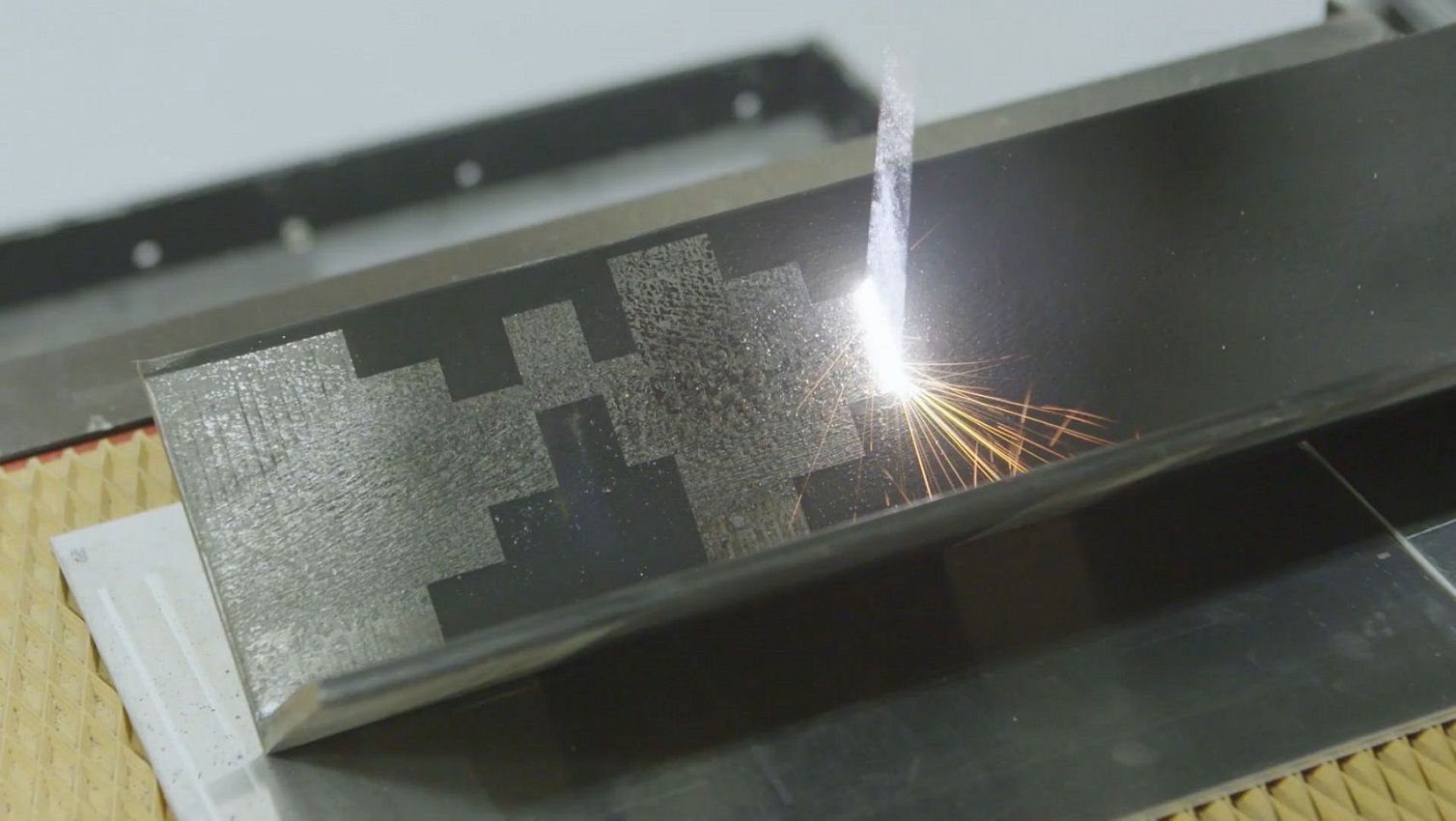

Laser cleaning is an environmentally-friendly and cost-effective method that can be used on both metal and non-metal surfaces. The laser generates heat, which vaporizes any unwanted gunk, rust, corrosion, or paint splatters from surfaces. This makes it one of the fastest cleaning processes available today. Fiber laser cleaning is also an excellent option for pre-treating workpieces before painting and is efficient enough for restoring or recycling mechanical products.

We can utilize laser beams with energy densities ranging from 107W/cm2 to 1010W/cm2 to effectively remove contaminants or rust layers from surfaces through vaporization.

+86 18151106863

+86 18151106863 info@airtronicstech.com

info@airtronicstech.com