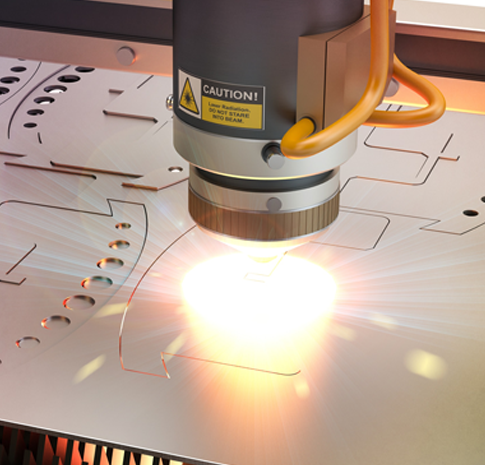

The sheet metal industry has experienced significant growth in recent years and can now be found across a multitude of industries. Laser cutting technology has served as a catalyst for its rapid development, enabling it to expand its reach to include a wide range of applications, from household appliances and instrument metal shells to road billboards, garbage cans, charging piles, and car washing machines, among many others.

APPLICATION ENGINEERING

Successful laser solutions

Fiber lasers are highly versatile, offering a wide operating power range that enables their beam focus and position to remain constant even as laser power changes. Spot sizes can be varied through simple optics configuration adjustments. This makes fiber lasers ideal for cutting a wide range of materials and wall thicknesses, without losing focus or consistency in terms of power density. AeeFar Airtronics Tech fiber lasers are the perfect solution for these needs.

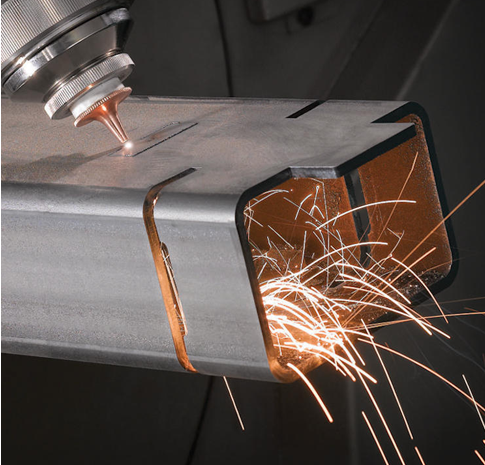

Air-tronics confidently offers a wide range of laser heads suitable for tube and profile laser cutting applications of all complexities. Our 2D and 2.5D cutting heads are adaptable depending on contour complexity. Our highly automated laser systems are equipped with motorized focus position adjustment, sensor monitoring, and control functions, ensuring the highest quality and desired results for our users.

Advertising metal word industry

Thanks to the high precision laser cutting technology, secondary rework is not required for cutting surfaces. This results in a significant increase in work efficiency and a reduction in the costs associated with enterprise operations when compared to the poor machining accuracy and cutting surface of traditional processing equipment.

Shipbuilding industry

With laser cutters, you can produce marine steel plates of exceptional quality and precision. These plates have no slag, thin oxide layer, or rough surfaces on their cut surfaces. Welding can take place directly without the need for secondary processing steps. You can also enjoy minimal thermal deformation, high curve cutting accuracy, reduced working hours, and barrier-free cutting of high strength ship plate. Trust laser cutters to provide you with top-notch results every time.

Electronics

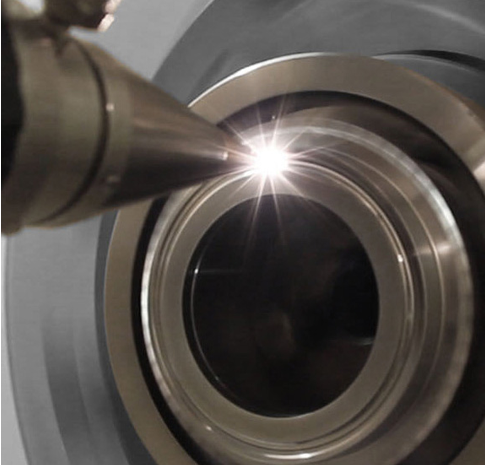

At Air-tronics, we know that sheet metal designs are common for switching cabinet housing, plug-in units, and electrical device housings. That's why we've developed laser cutting machines that can process these components with ease, saving our customers valuable time and money. Our machines also utilize laser welding technology, which guarantees superior seam quality and minimizes the need for any additional reworking. Trust us to provide you with the highest quality results, every time.

Sports equipment

Fitness equipment presents unique processing challenges, but traditional approaches are often inefficient and time consuming. Laser cutting's versatility makes it the ideal solution to meet these high requirements, with tailored flexibility that allows it to process different pipes and plates smoothly, without the need for secondary processing steps. Air-tronics tube cutting machines also enable efficient mass production of fitness equipment, while laser cut technology guarantees high precision of each component and assembly produced. With these cutting-edge solutions, we can confidently deliver high-quality fitness equipment to meet the needs of our customers.

Furniture making and shopfitting

Furniture makers utilizing sheet metal frames, such as cabinet systems or tables, are required to produce weld seams quickly while still maintaining a high level of aesthetic appearance. In this regard, laser welding stands out as the optimal choice, offering customers significant cost savings when compared to conventional arc processes for visible seams. Furthermore, laser welding provides manufacturers of professional kitchens with an added advantage as its tightly sealed seams help prevent subsequent germ formation. Precision cutting of sheet metal parts, tubes and profiles opens up creative freedom for furniture manufacturers. Air-tronics laser tube cutting machines enable customers to craft precise miter cuts for high-quality and efficient designs. When applied to shopfitting projects, the machines allow for individual parts or series production with flexibility, enabling individual projects to be realized cost-effectively and efficiently.

Customer Benefit

With laser technology, customers can enjoy the following benefits:

-

Fast cutting speeds improve production efficiency and greatly shorten production cycles.

-

Narrow cuts, high-quality cutting, and excellent material adaptability enhance product quality.

-

High levels of automation and easy operation reduce labor intensity.

-

Processing is pollution-free and does not harm the human body.

-

Laser technology does not cause tool wear, which reduces operating and material costs.

-

High reliability and strong stability meet the demands of mass industrial production with ease.

+86 18151106863

+86 18151106863 info@airtronicstech.com

info@airtronicstech.com