Laser Welding

What is Laser Welding

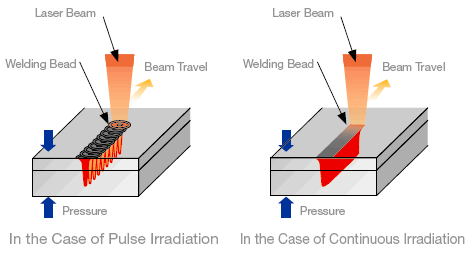

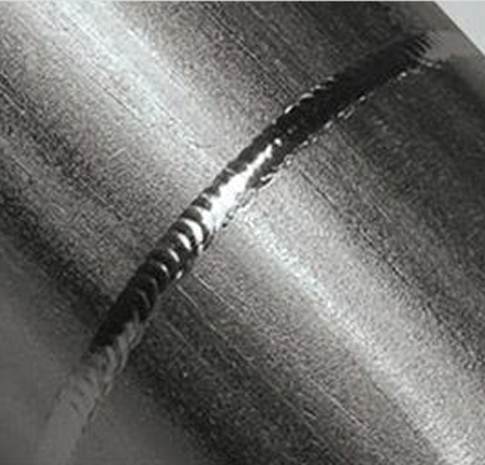

Laser welding (LBW) is a process that uses lasers to melt material on the surface of workpieces, allowing them to be joined together with another piece made from similar material. This technique is commonly applied to metals or thermoplastics. Different types of lasers, including solid-state or gas lasers, are employed in laser welding applications today.

With their high power density, lasers are capable of precisely melting the material of workpieces. This occurs when molecules near the surface are subjected to a powerful laser beam, causing them to become excited and take on fluid-like characteristics. When excited molecules of similar material meet each other and transition down excitation states simultaneously, solid structures reform and molecular bonds form on a molecular level. This process enables pinpoint precision and reliable results.

Advantages of laser welding

High-speed laser welding offers several benefits, including:

■High-precision accuracy, even for small parts

■Low heat input, resulting in minimal distortion

■Non-contact welding, which prevents degradation in welding quality

■No current passing through the part

■Ability to weld dissimilar metals, such as Cu to Al

■Minimal maintenance required, ensuring high tool availability

■High productivity and yield, thanks to easy automation

■Overall, high-speed laser welding provides a cost-effective solution, with high part yields at low operating costs, resulting in the lowest cost-per-part.

Discover the versatility of lasers 3

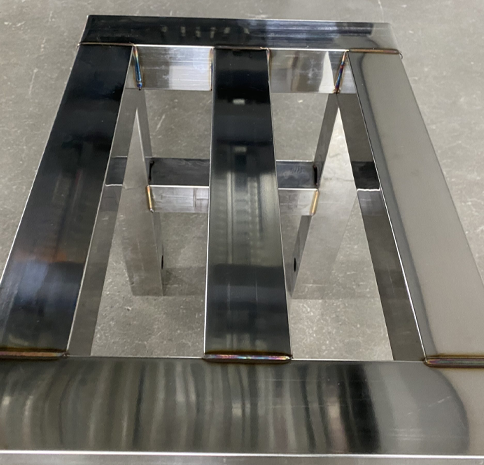

Laser welding is a standout technology in modern manufacturing, thanks to its incredible versatility. With its flexibility for joint geometry, laser welding is the ideal choice for industries producing a range of products. Moreover, it is more energy-efficient, faster, and more precise than traditional welding methods. In fact, modern welding machines even operate automatically, providing another key element of modern production. Laser welding is undoubtedly the way to go for any industry looking to keep up with the demands of modern manufacturing.

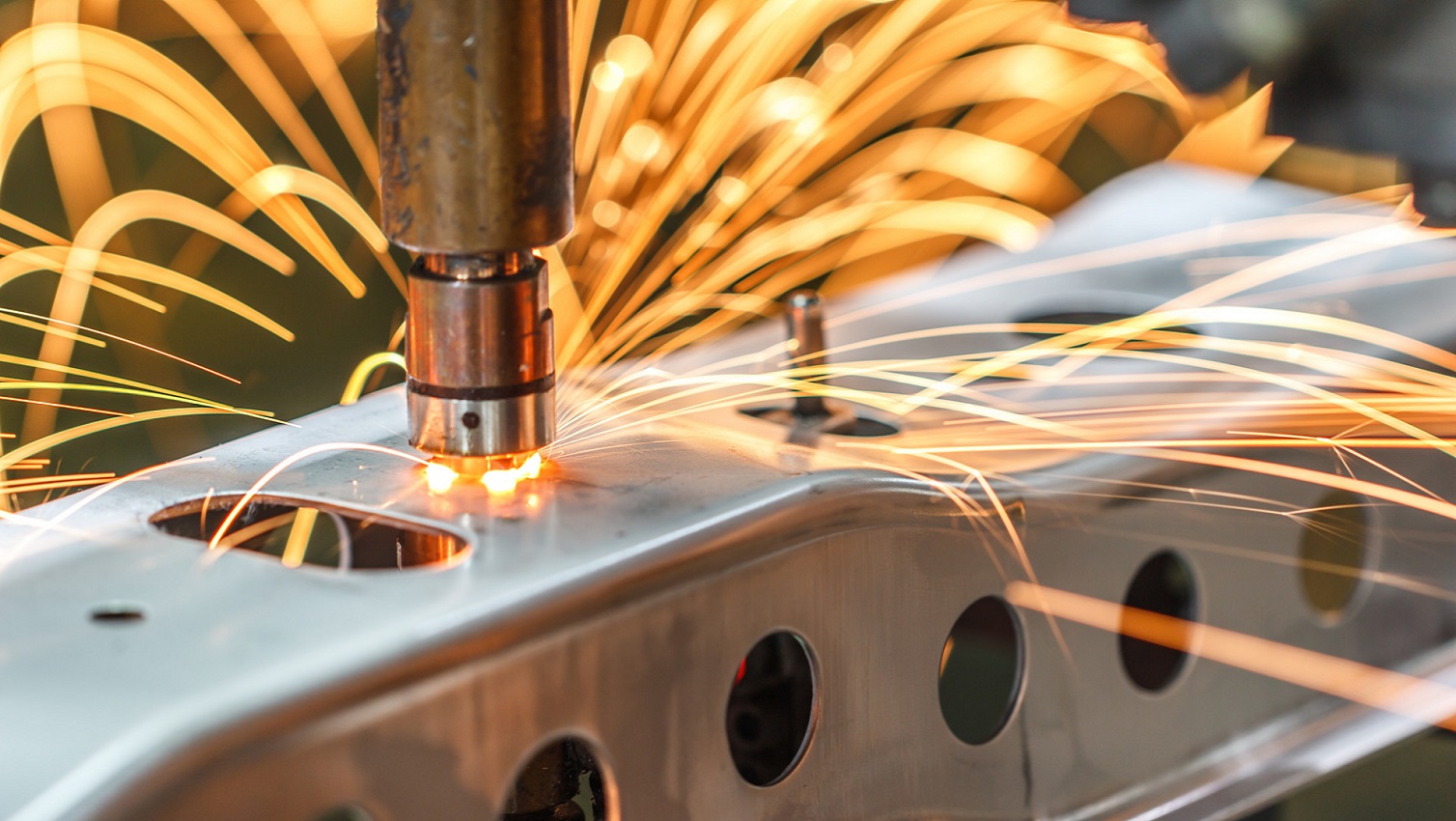

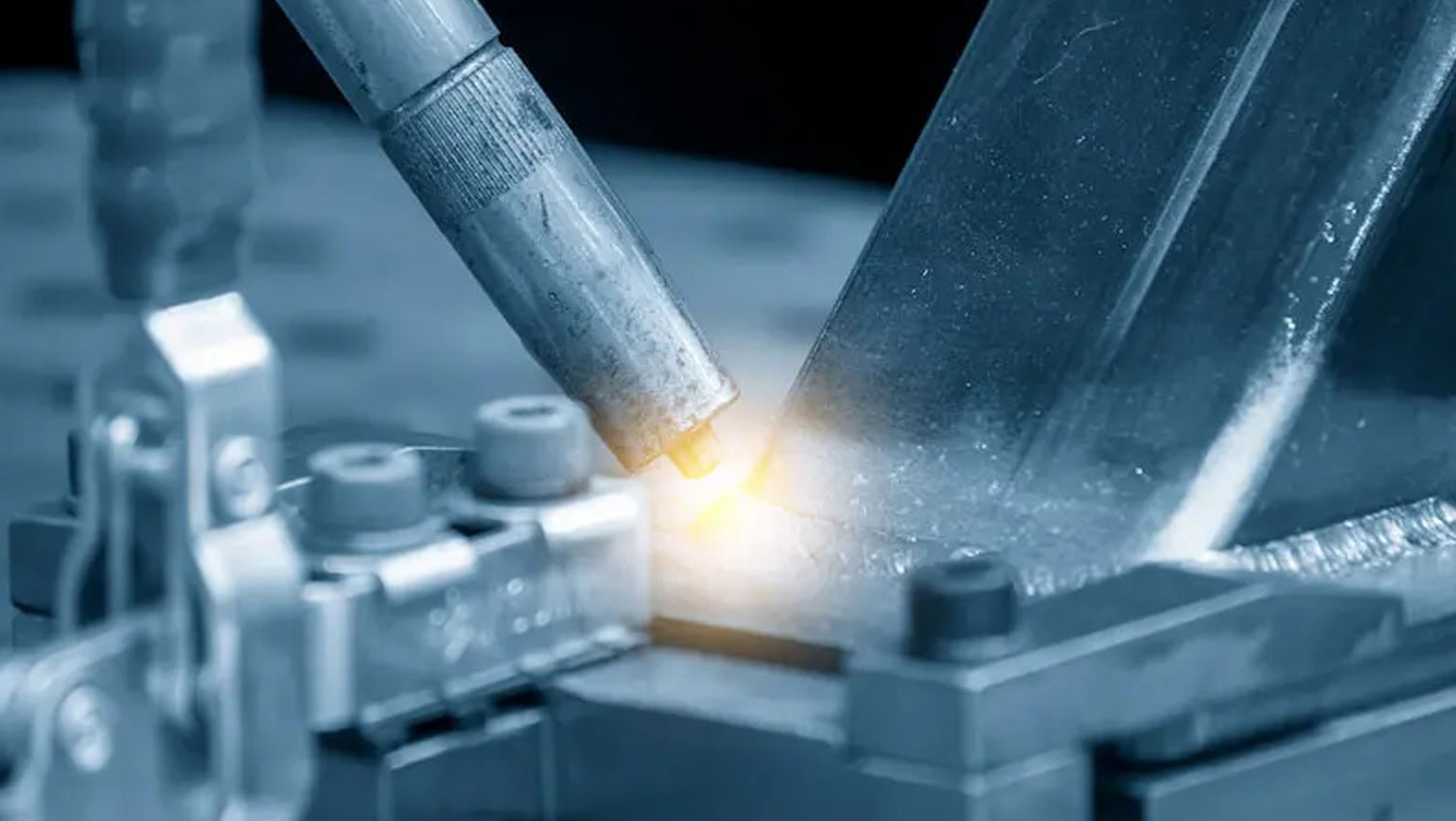

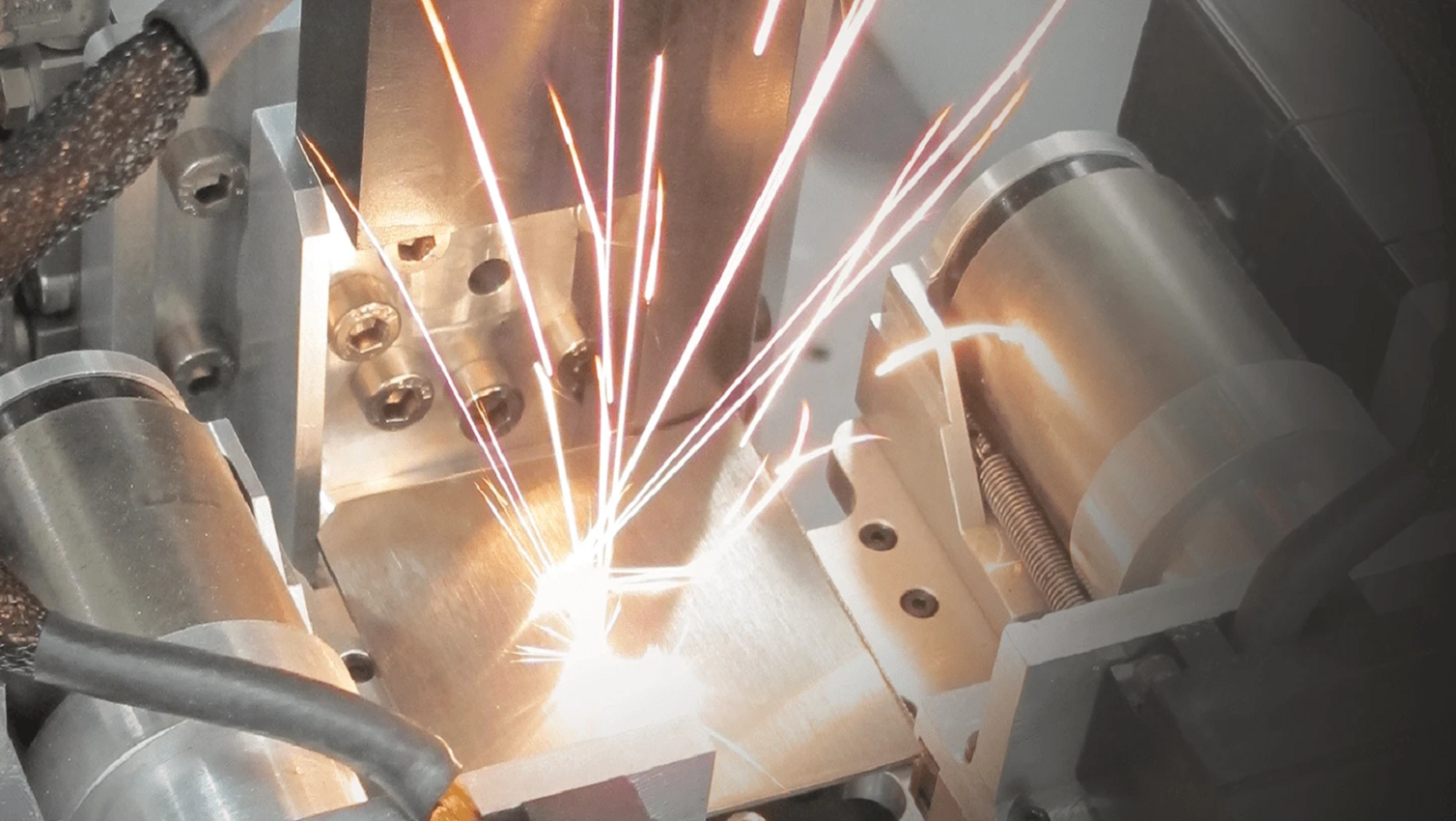

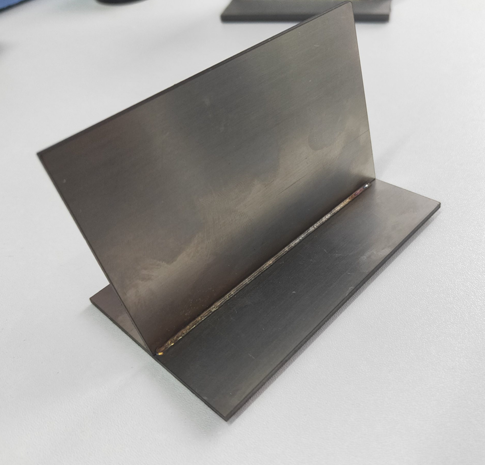

Examples of laser welding applications

+86 18151106863

+86 18151106863 info@airtronicstech.com

info@airtronicstech.com