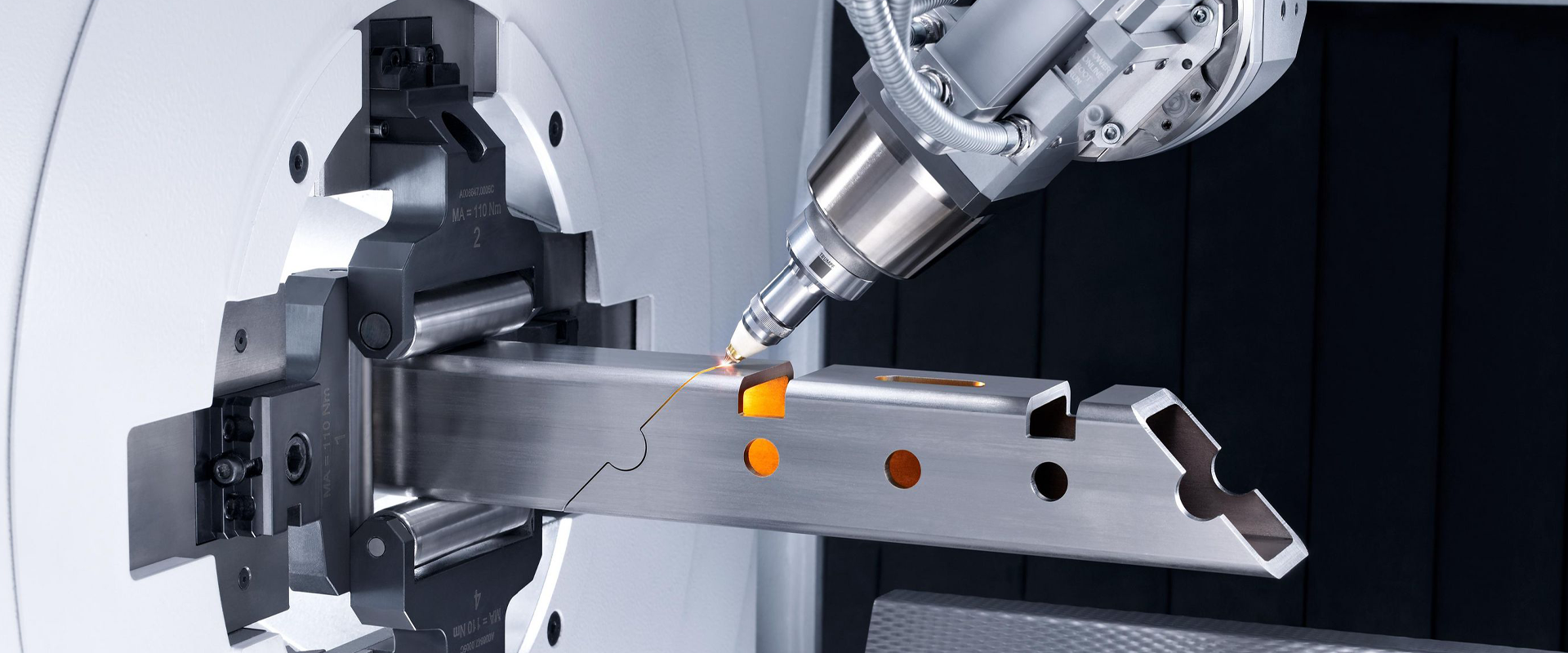

Lasers are essential to modern manufacturing because they provide accurate measurements and intricate designs. Laser machining allows the creation of small details that are challenging or impossible to produce with conventional equipment. Furthermore, laser cutting doesn't cause any heat damage or rough edges on nearby materials, which reduces the need for additional finishing steps. As a result, laser machining is a crucial process in additive manufacturing and Industry 4.0.

APPLICATION ENGINEERING

Successful laser solutions

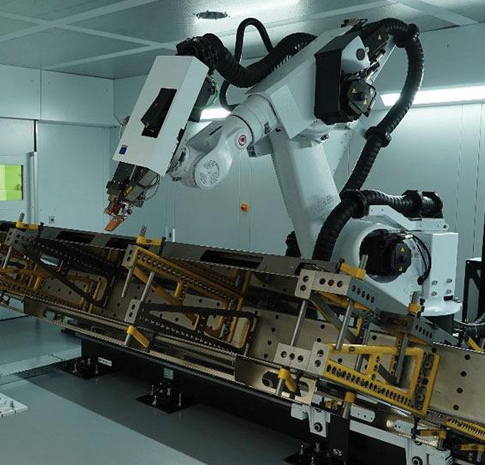

In the manufacturing industry, engineers often rely on high-power lasers to solve a variety of manufacturing challenges. These lasers are exceptionally efficient, precise, and eco-friendly, making them a dependable alternative to other manufacturing technologies. Engineers frequently use high-power lasers for a range of operations, including laser marking, cleaning, texturing, welding, and cutting on fast production lines. By utilizing high-power lasers, engineers can quickly and confidently produce high-quality products.

Laser Welding Applications

When manufacturing ships, cars, and aircraft, laser welding is the preferred choice for industry leaders. Fiber lasers are particularly favored, as they are more compatible with materials, produce higher quality welds, and can be automated. Not only is this technology faster to learn than traditional welding, it is also safer, making it the best option for companies seeking to stay ahead of the curve.

SHIPYARDS

Laser cleaning has numerous applications in shipyards for surface cleaning. Various applications to be considered include:

1. Spot repair or spot preparation

2. Weld or glue preparation

3. Removal of light rust on uncoated areas

4. Non-Destructive Testing (NDT)

TRAIN INDUSTRY

Laser cleaning is a dependable method used by the railway industry to strip old coatings from train carriages. Since these carriages are regularly repainted, caution is crucial due to the presence of lead paint or Cr6 components containing lead. Fortunately, laser cleaning offers an effective and efficient solution by eliminating toxic dust and fumes through its reliable vacuum system.

Applications

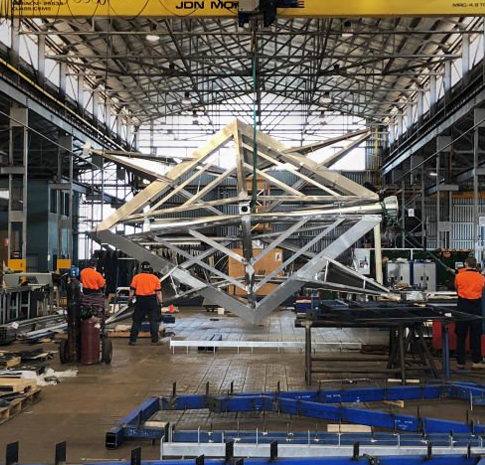

Shipbuilding industry: This industry is involved in sheet welding, surface preparation, and paint removal.

Railway industry:In the railway industry, carriage welding, locomotive engine manufacturing (including complete integrated systems), railway line welding, and railway track cleaning from greasy fallen leaves deposits are some of the processes involved.

Yellow goods industry:The yellow goods industry involves crane boom welding, cladding of earth mover devices after wear and tear.

Power generation industry: The power generation industry is responsible for cladding and repair of turbine blades and journal shafts.

Oil and gas industry:The oil and gas industry carries out pipeline welding, pipeline inspection, remote dismantling, and oil well drilling (transmission through kilometers of optical cable to heat hard rock types to improve drilling productivity).

Construction industry: In the construction industry, the processes involved include concrete removal (scalping), concrete drilling, and steel beam welding.

Super structure manufacturing: This industry deals with the complete laser welded bridges.

+86 18151106863

+86 18151106863 info@airtronicstech.com

info@airtronicstech.com