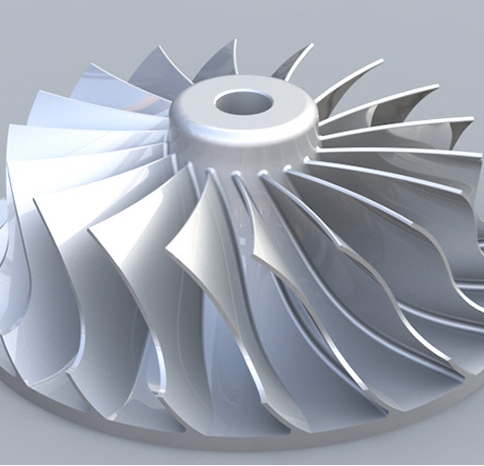

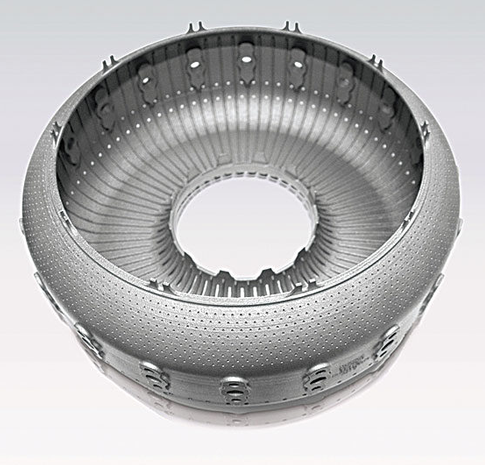

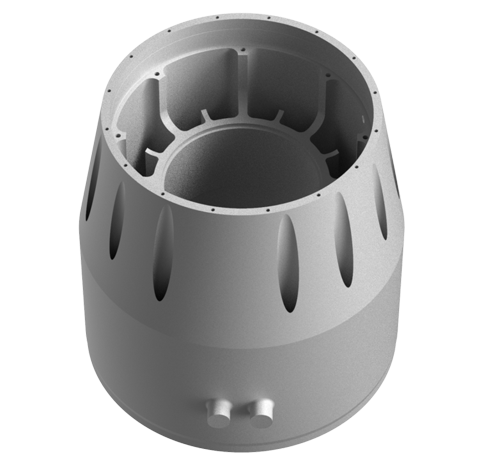

In the aerospace industry, the application of laser technology is witnessing steady growth due to the increasing demand for enhanced fuel efficiency. Lasers play a crucial role in welding high-strength steel components and brazing large sheet metal pieces, as well as cutting fiber-reinforced polymers for weight reduction purposes and welding high-strength steel alloys. Laser technology is extensively used in the production processes of aircraft turbine manufacturers. Every engine contains blades and vanes that are laser-drilled, cut, clad, or additively manufactured during assembly operations. Laser technology is utilized for meeting the stringent quality requirements of components like turbine, compressor, and blisk blades. Laser applications, such as paint stripping, also play a vital role in aerospace production and maintenance.

APPLICATION ENGINEERING

Successful laser solutions

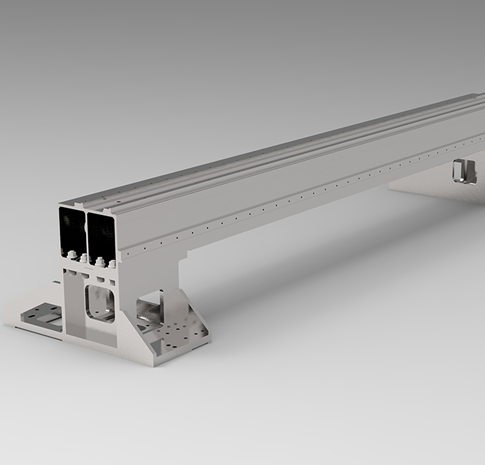

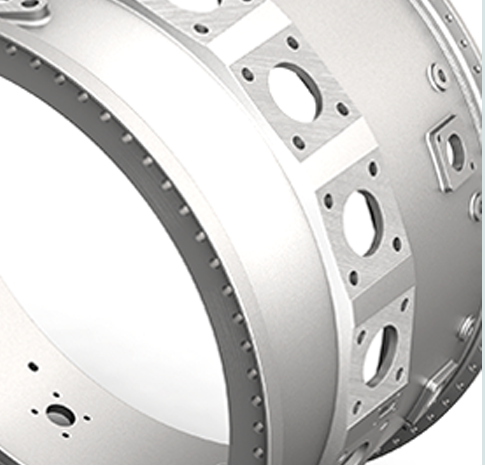

Aviation and aerospace customers can significantly reduce costs by using laser metal deposition (LMD) to repair blisks (blade integrated disks) or compressor/turbine blades instead of buying replacement parts. LMD allows for precise restoration of damaged components, which eliminates the need to purchase new ones. With LMD, we can achieve geometric adjustments, repairs, and production of high-quality components such as housings with precision. Our lasers can also cut, weld, mark, drill, and process surfaces in aviation/aerospace applications, resulting in substantial cost savings compared to purchasing new replacement components.

+86 18151106863

+86 18151106863 info@airtronicstech.com

info@airtronicstech.com