HI series products feature several patented technologies, such as hollow/semi hollow structure machine tools, boneless workbench structures, timesharing/zoning/segmented dust extraction structures and cutting head double cooling structure technology. Thick plate cutting efficiency has improved and remains more reliable. The new generation qh.spac intelligent cutting system boasts flexible operation, more perfect and intelligent functions, improved leapfrog speed and efficiency, fast intelligent perforation mode and fast intelligent knife receiving mode, as well as being configured with expert process databases more suitable for user use. Furthermore, convenient industrial intelligent interfaces such as intelligent remote cloud interfaces and transportation diagnosis modes further facilitate their use.

Laser Metal Cutting Machine: A Comprehensive Guide

Laser metal cutting machines are an essential tool for modern manufacturing. They use laser technology to cut through metal sheets with precision and speed, making them ideal for a wide range of applications.

Laser metal cutting machines use a high-powered laser beam to melt and vaporize metal sheets. The laser beam is directed by a series of mirrors and lenses to the cutting area, where it creates a narrow kerf in the metal. This kerf is so small that it is almost invisible to the naked eye, which allows for extremely precise cuts.

Laser metal cutting machines offer several benefits over traditional cutting methods. Some of the most significant benefits include:

Laser metal cutting machines are used in a wide range of industries, including automotive, aerospace, and electronics. Some of the most common applications of laser metal cutting machines include:

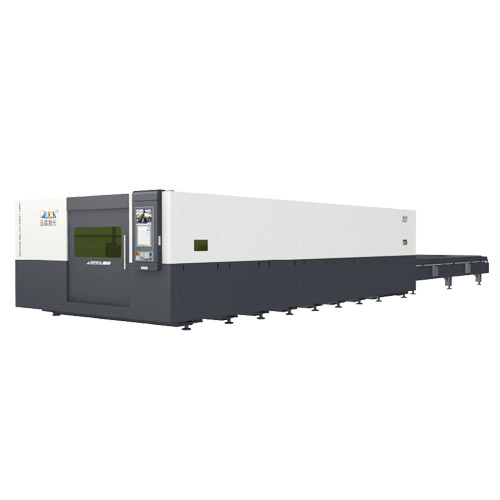

The Quick-PC machine is an advanced fiber laser cutting machine with a full protective cover design. It boasts a wide range of machine power, with options ranging from 1000W to 30000W.

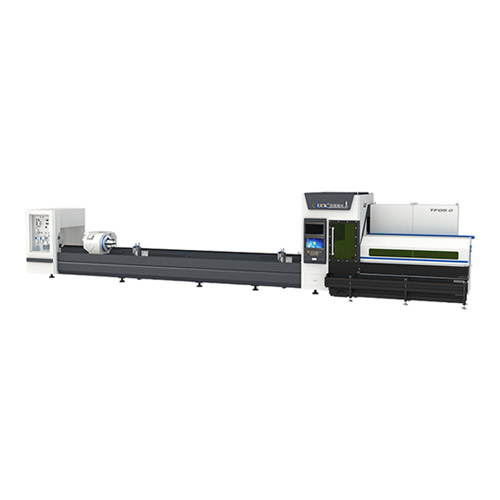

Our automatic pipe laser cutting machine is designed to provide users with exceptional ease-of-use, allowing for simple adjustments and seamless application when cutting a wide variety of pipe sizes and shapes. With an advanced automatic adjustment chuck, our machine is the perfect choice for any cutting needs you may have.

Our design and engineering teams have worked with customers from every industry to design, manufacture, and deliver marking solutions built for specific applications.

Metals to polymers, thick to thin, large to small, lasers can do it all. we can offer you comprehensive advice for all production possibilities.

Customer Service Products Privacy Imprint Company

2023 Air Tronics